WORK PORTFOLIO

MENSTRUAL PAIN RELEIF DEVICE FOR WOMEN (POMwear)

PERIOD- STARTUP AT NORTHWESTERN December 2024 - Jan 2025

What is a POMwear?

POMwear is a emerging startup where we’re developing a device to alleviate menstrual pain for women.

Developing a multifunctional device with the following features:

- TENS (Transcutaneous Electrical Nerve Stimulation): Relieves pain by stimulating nerves and blocking pain signals to the brain.

- Heating/Cooling Therapy: Alleviates cramps and chronic pain while aiding in the treatment of conditions like endometriosis and PCOS.

Design Concept Team

Currently working with superb team at POMwear in design concept team mainly focusing modeling of the device and general functionality.

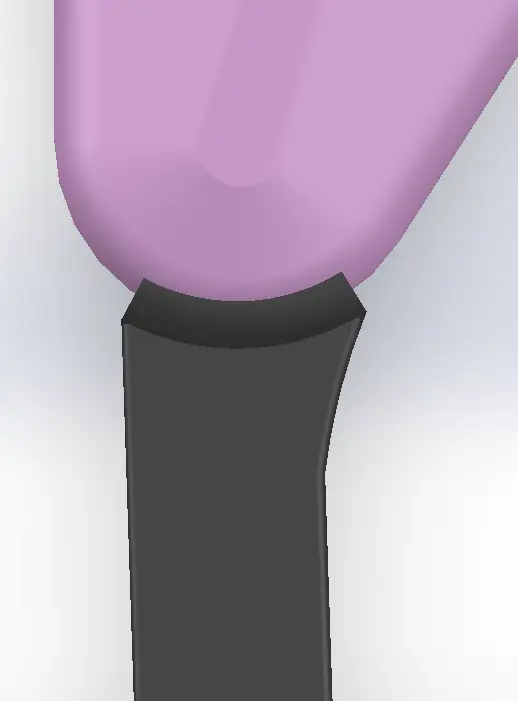

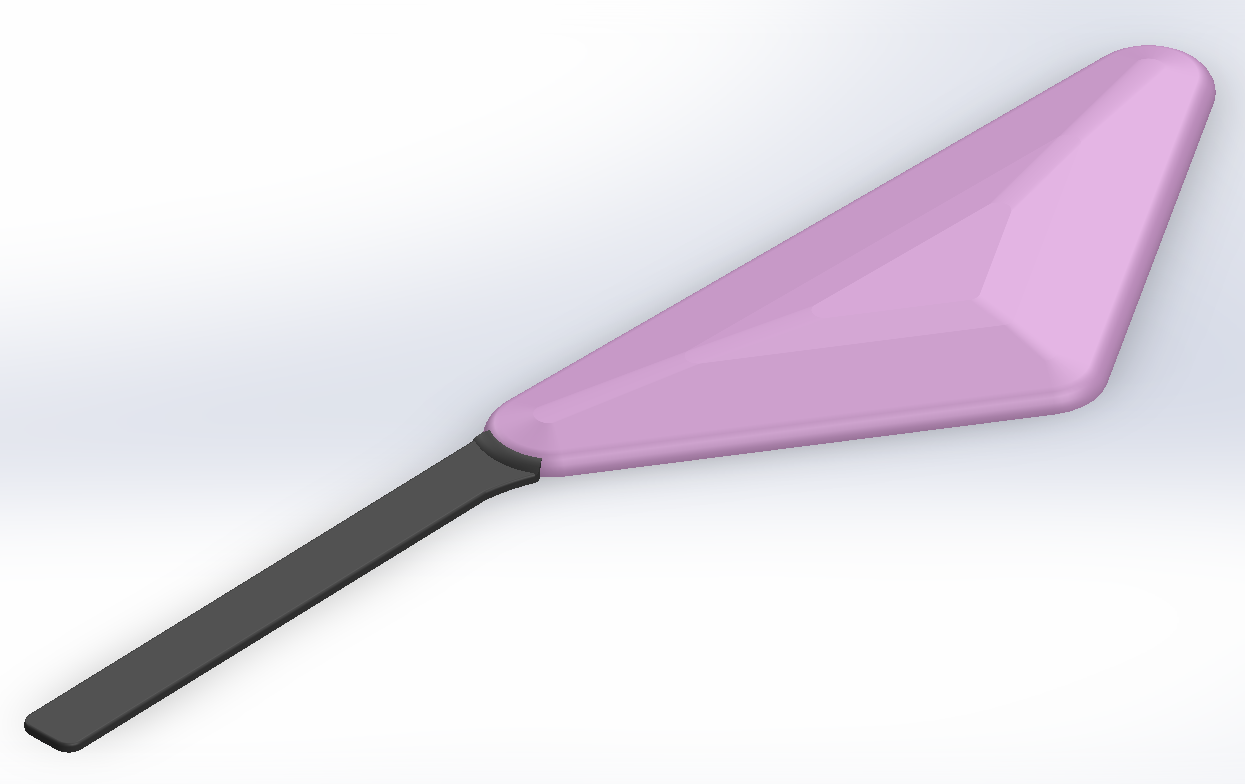

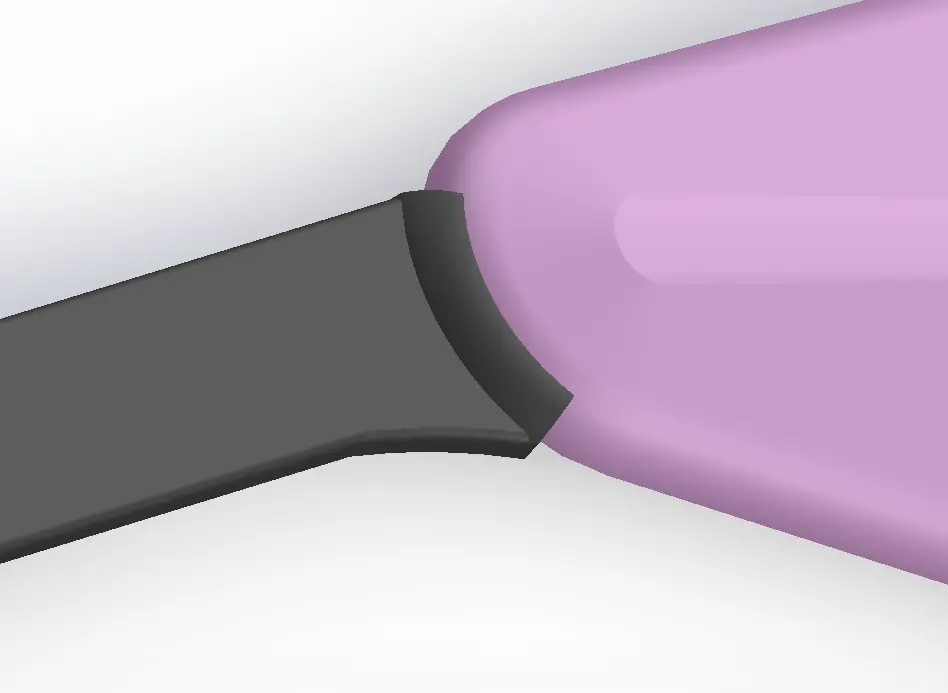

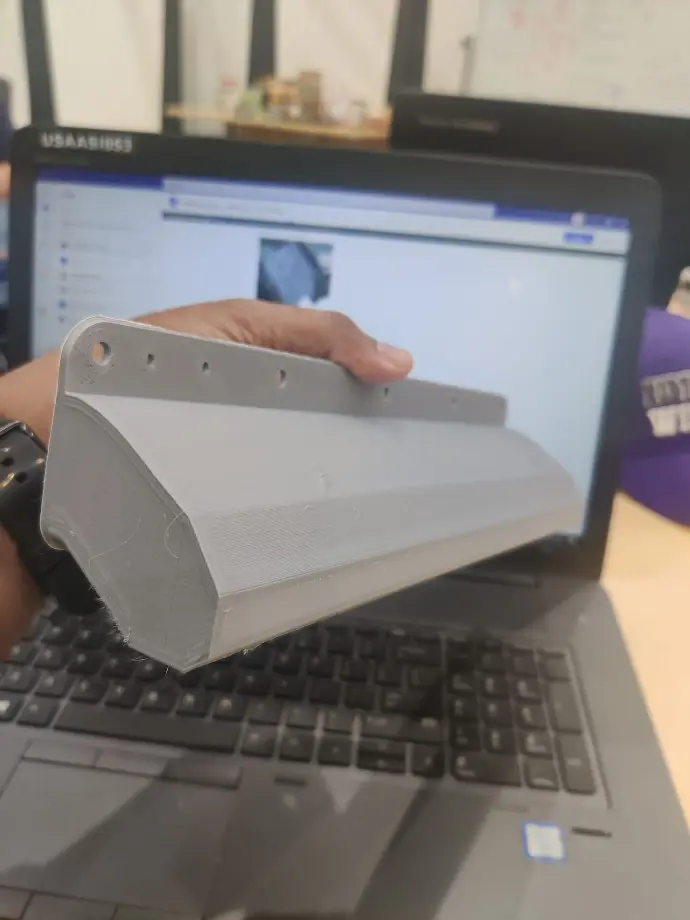

LOOKS LIKE MODEL

- The images above showcase the initial design model for the front part of the POMwear device.

- The design is based on insights gathered from a university feedback session and a literature review analyzing existing devices and their functionalities.

PARAMETER OPTIMIZATION OF 3D PRINTED PART USING PREDICTION MODELING

PERIOD- MS THESIS PROJECT AT NORTHWESTERN December 2024

POWDER BED FUSION

Additive Manufacturing technique that uses a laser beam to fuse powdered material layer-by-layer.

Enables intricate designs and overcomes limitations of traditional manufacturing and has a widely adopted in aerospace, automotive, and medical device manufacturing.

Importance of Optimization in Powder Bed Fusion

- Reduces defects and improves part density

- Enhances mechanical properties like tensile strength

PROBLEM STATEMENT

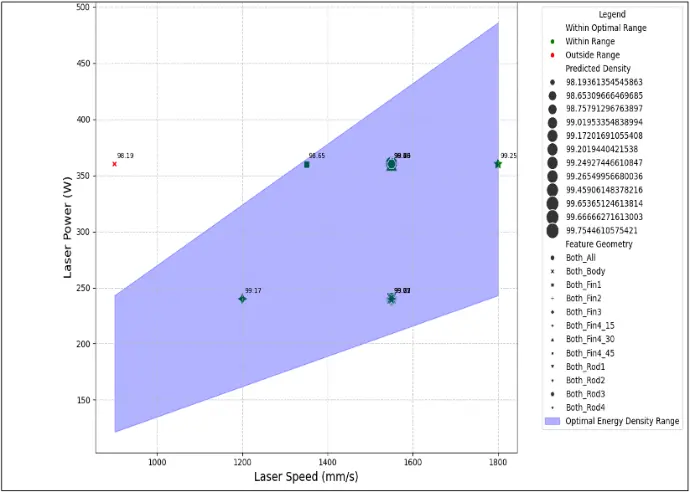

Traditional PBF optimization ignores cross-sectional variations, leading to inconsistent density. My model enables feature-specific parameter tuning for improved part quality, ensuring better mechanical properties and reduced defects.

EXPERIMENTAL SETUP

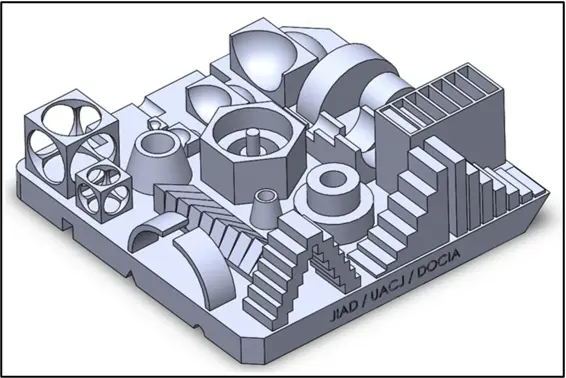

Used DMG MORI Lasertec 12 SLM with AlSi10Mg. Tested Zeiss geometric samples via XCT for non-destructive porosity and density analysis, capturing 96 data points across 8 samples with 12 unique features per sample.

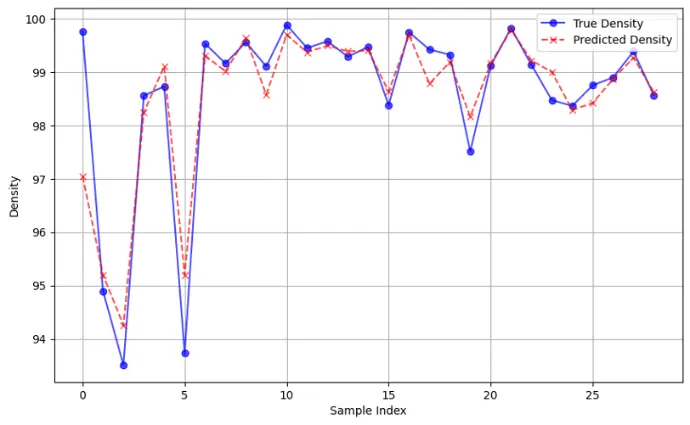

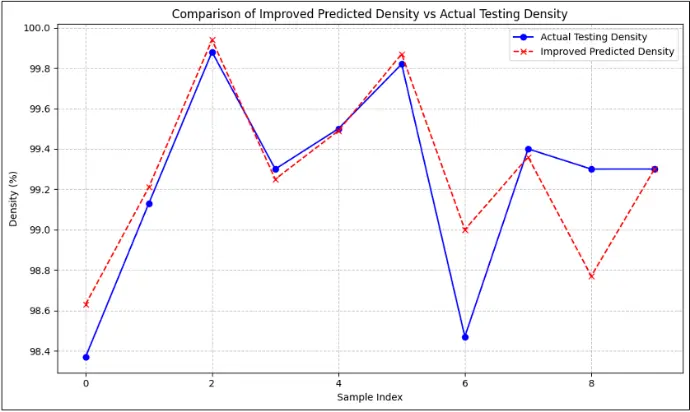

TESTING RESULTS

Feature-specific optimization improved density prediction, achieving 99% accuracy. The Gradient Boosting model outperformed others, demonstrating precise alignment with actual test results and effectively reducing experimental noise.

TRUE DENSITY VS PREDICTED DENSITY (GAUSSIAN PROCESS MODEL)

ACTUAL DENSITY VS IMPROVED PREDICTED DENSITY

PROCESS MAPPING GRAPH OF LASER POWER & SPEED

.

TACKLING POWDER OVERDOSE PROBLEM IN METAL 3D PRINTING

PERIOD- SUMMER INTERNSHIP AT DMG MORI AUGUST 2023

3D Printed Doser Prototype

WHAT?

Analyzed and improved powder overdosing in SLM machine achieving 28% boost in dosing precision by replacing motor with more reliable mechanical solution

3D Printed Doser Prototype

WHAT?

Analyzed and improved powder overdosing in SLM machine achieving 28% boost in dosing precision by replacing motor with more reliable mechanical solution

Experimental Setup for Powder Dosing

HOW?

CAD modeling of doser was done using Creo Parametric, 3D printing with Ultimaker Cura, and experiment utilized testing setup with diverter, flanges, and weighing machine

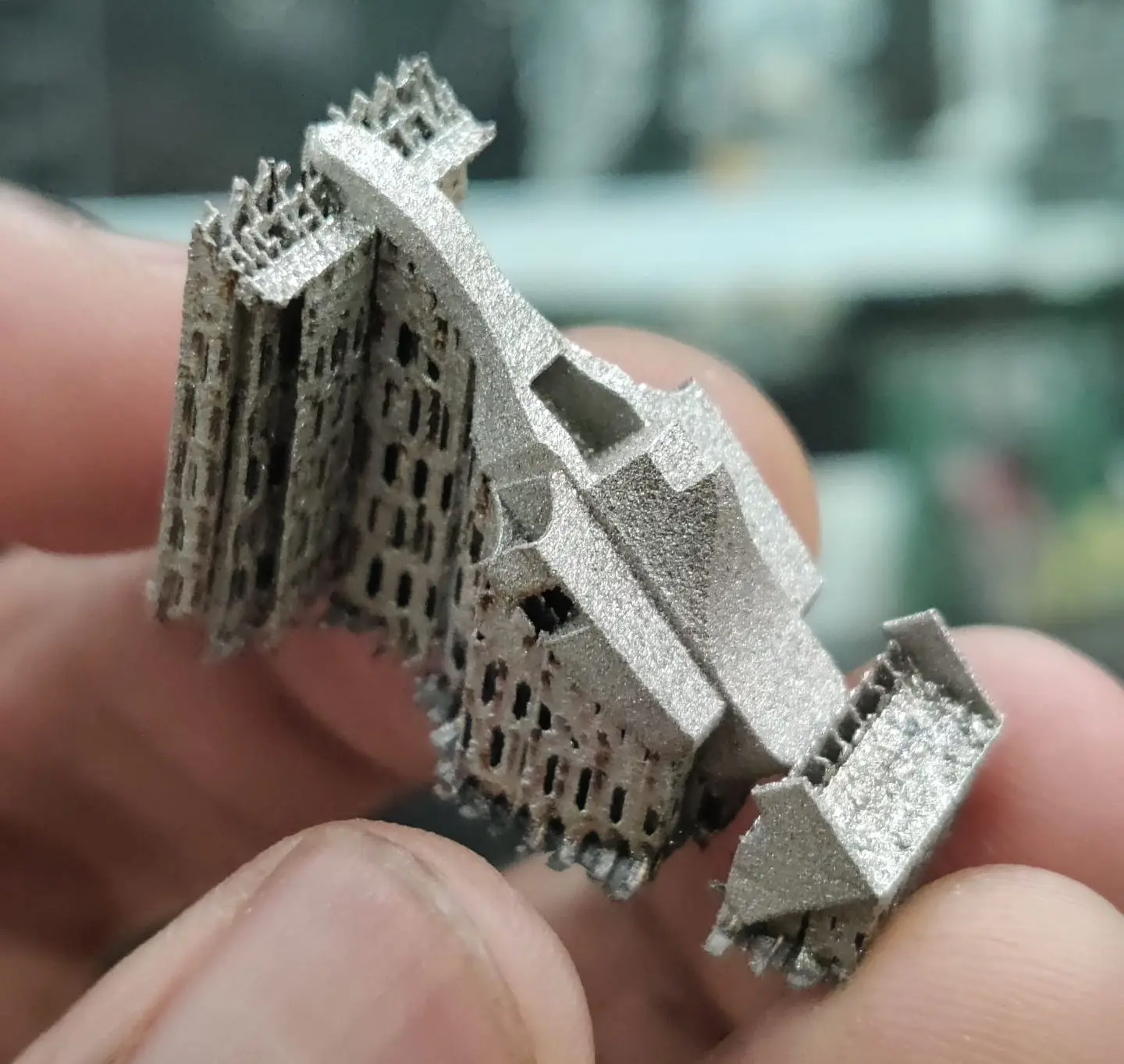

Metal 3D Printed Parts

RESULTS

Due to improvement in dosing, we experienced 40% decrease in the porosity of the parts

DMG Lasertec SLM Machine

Metal 3D Printed Part

3D Printed Mount

INSTALLATION EFFECTS OF A BUTTERFLY VALVE ON HYDRAULICS DEVICES

PERIOD- SEMESTER-LONG INTERNSHIP AT CWPRS JUNE 2021

Experimental setup for flowmeter

WHAT?

Addressed impact of installation conditions on accuracy of flow meters in hydro turbines, given limitation of straight lengths affecting flow

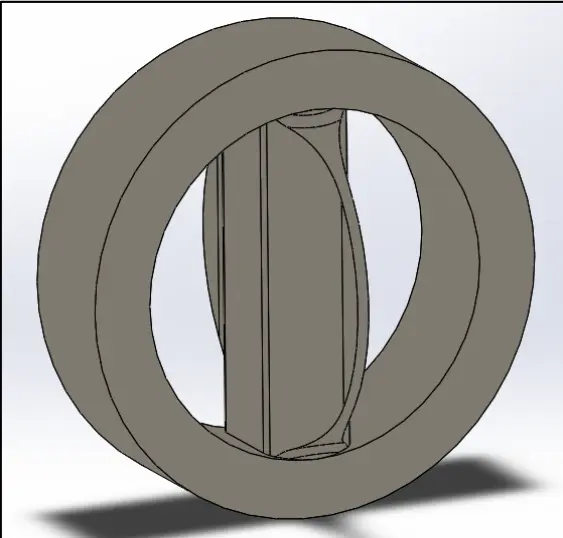

CAD Model of Butterfly Valve

HOW?

Utilized Ansys CFD Fluent solver, Hypermesh, SolidWorks, and hydraulic experiments to optimize and validate system

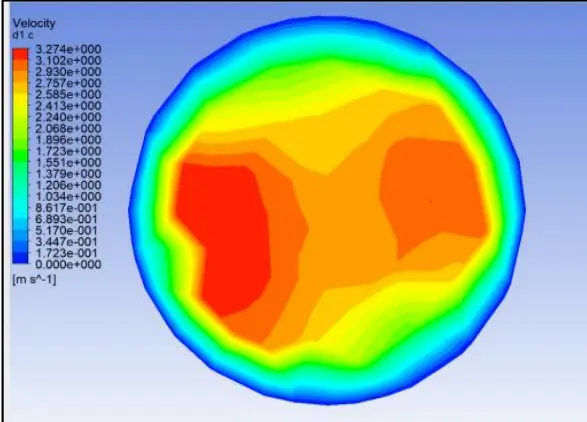

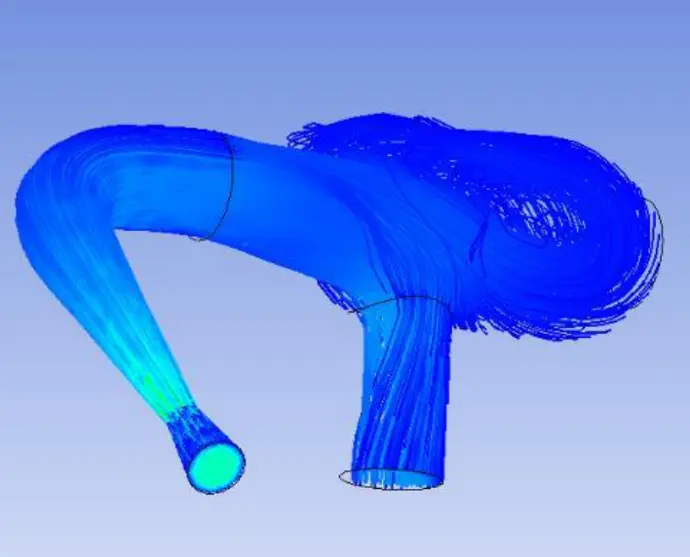

Velocity Profiles of butterfly valve

RESULTS

Result shows that installation conditions significantly impact flow meter accuracy, with errors depending on pipeline straight length, achieving minimum error of 0.06%

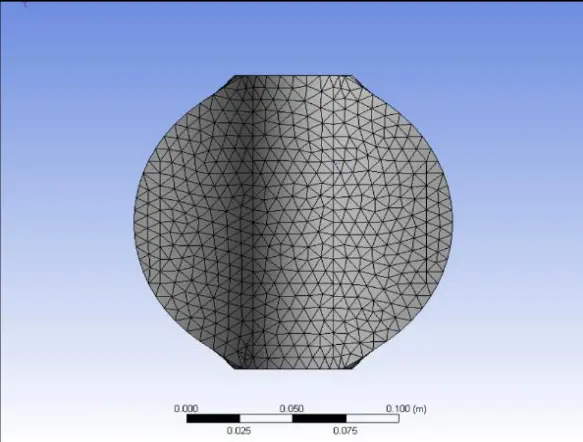

Meshing of Butterfly Valve

Meshing of Butterfly Valve

Used Ansys CFD Fluent solver and Altair HyperMesh to mesh, model, and analyze velocity distortion caused by the butterfly valve. The image shows the butterfly valve flap meshed with fine tetrahedron mesh in HyperMesh and hexahedron mesh in Ansys, allowing for a comparison of results between both software tools.

DESIGN AND SIMULATION OF AIR INTAKE FOR FORMULA 1 PROTOTYPE CAR

PERIOD- FORMULA STUDENT TEAM AT VIT PUNE JANUARY 2020

CAD Model of Air Intake

WHAT?

Project designs intake manifold to maximize engine efficiency and power, assessing fiber-reinforced plastic, 3D printing, and metal for their strengths, weaknesses

Thermocole Base for Carbon Fiber Intake

HOW?

Intake manifold was designed using SolidWorks, incorporating surface features tool for precision. Key features such as plenum volume, runner length was analyzed

CFD Analysis of Air Intake

RESULTS

Result was 3D-printed air intake for racing engines, reducing assembly weight by 600 grams and increasing brake power by 18%

Formula Student club is where we design, manufacture, and test Formula 1 prototype car for participation in national and international Formula Student competitions. Notable competitions include Formula Student Germany (FSG) and Formula Student Michigan

Spearheaded team of 50 Design Engineers focused on building racing cars for Formula Student competitions

Engaged process flow charts and control plans to amplify team performance, manage deadlines, and make critical design decisions

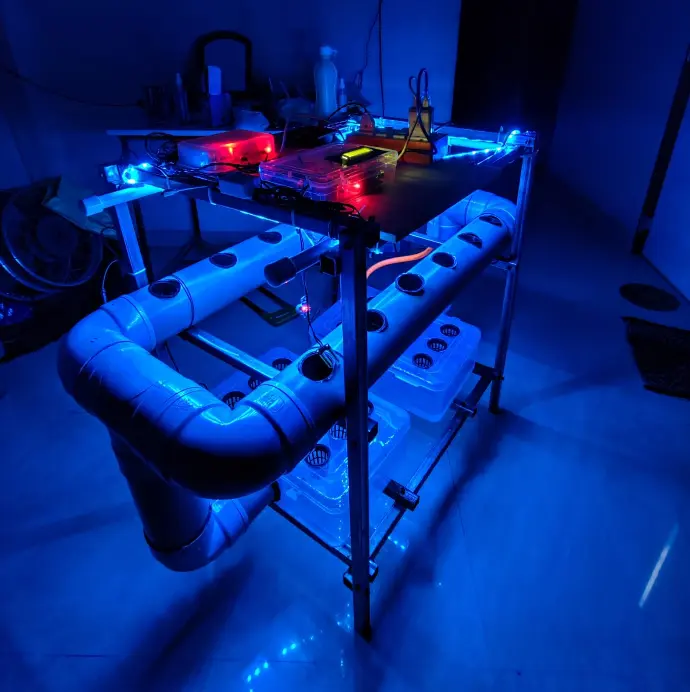

SOILLESS AGRICULTURE USING VERTICAL FARMING METHOD

PERIOD- MAJOR PROJECT BACHELORS AT VIT PUNE DECEMBER 2020

Germination of Plants

WHAT?

The study focuses on creating and optimizing a fogponic system, using fog to provide nutrients to plants and potentially increasing agricultural efficiency

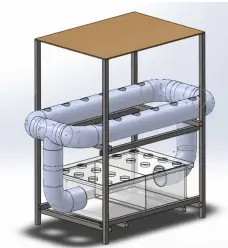

Fogponics 3D Model

HOW?

Developed using SolidWorks, Arduino, and Ansys CFD, includes creating infrastructure, selecting plant types, and experiments

Final Results

RESULTS

Result is an effective system for growing plants using less water and space than conventional methods

Fogponics Model Prototype

An advanced form of hydroponics that utilizes a fog or mist to deliver nutrients to plants. This method is considered a solution to the challenges faced in traditional agriculture, especially in areas with limited arable land

▪ Explore the viability and efficiency of Fogponics as a sustainable and space-efficient agricultural method.

▪ It seeks to address the growing need for alternative farming practices due to the increasing global population and decreasing availability of farming land.

DATA-DRIVEN EXTRACTION OF DED FLAW LOCATION VIA EMISSIONS MONITORING

PERIOD-COURSE PROJECT NORTHWESTERN UNIVERSITY DECEMBER 2022

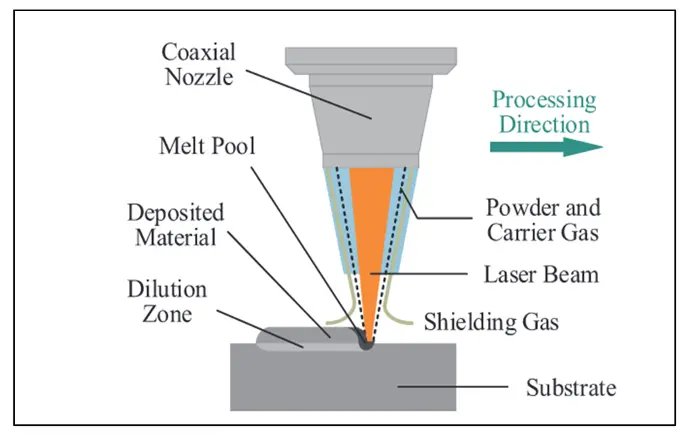

Direct Energy Deposition (DED) WHAT?

In an additive manufacturing process, we use directed Project aimed to predict location of flaws in thin wall during

laser light to melt the metal powder and deposit it layer DED process using simulated in-situ Acoustic Emissions data

Direct Energy Deposition

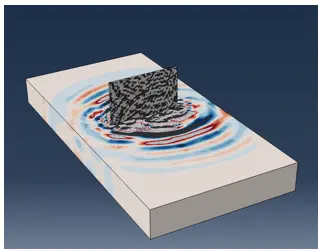

Dynamic FEA Simulation on Abaqus

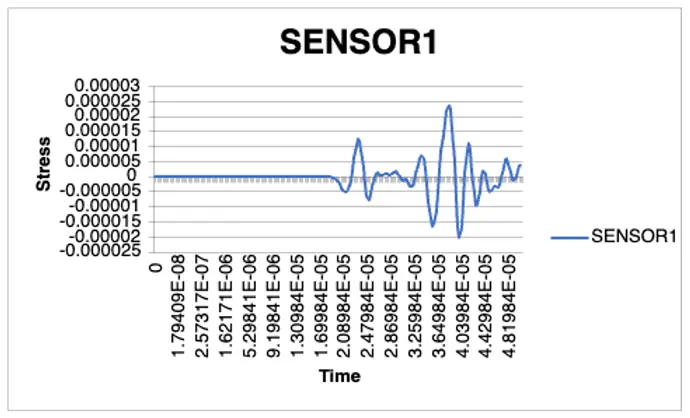

Preprocessed Data from One of Sensors

Correlation Matrix

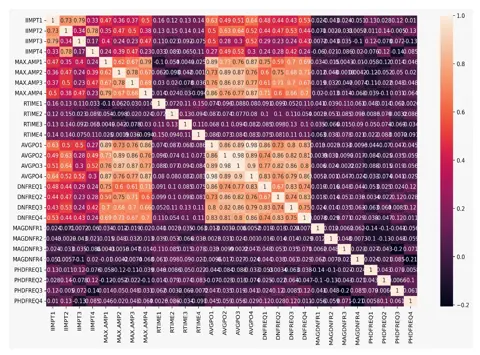

HOW?

Plotted correlation matrix to understand features. Some features are hugely correlated to each other. Plotted 28 features for the matrix

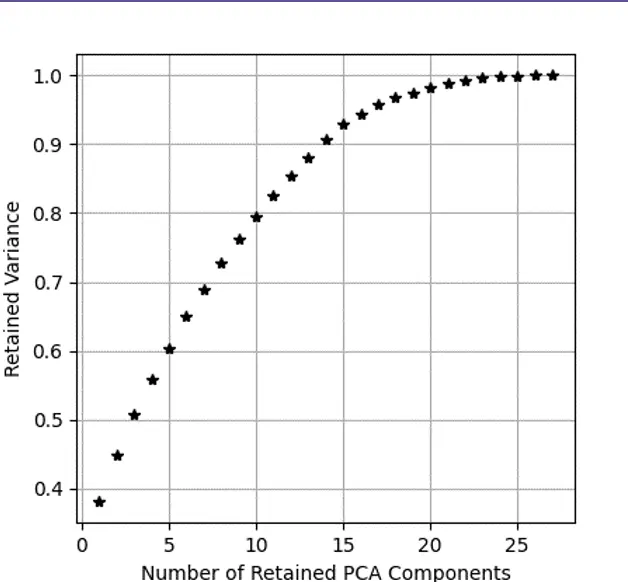

PCA Analysis

HOW?

Used Principal Component Analysis (PCA) to reduce dimensions to 11 principal components

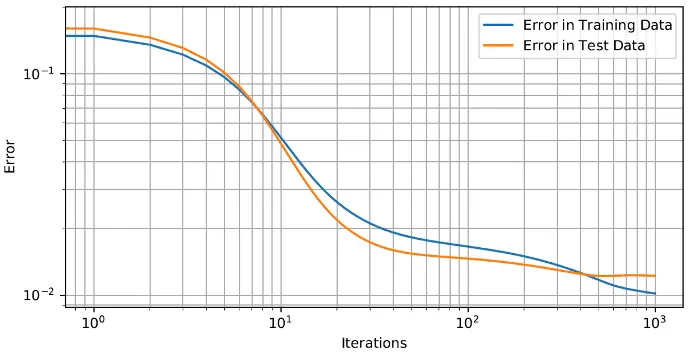

Graph Between Training Data and Test Data

RESULTS

Build FF Neural Network with Adam optimizer which is trained using 95% k-fold validation data. FFNN achieved 95% accuracy in predicting x & y coordinated of flaw location

HYPERPARAMETER TUNING OF CNN USING CENTRAL COMPOSITE DESIGN

PERIOD- COURSE PROJECT NORTHWESTERN UNIVERSITY MARCH 2023

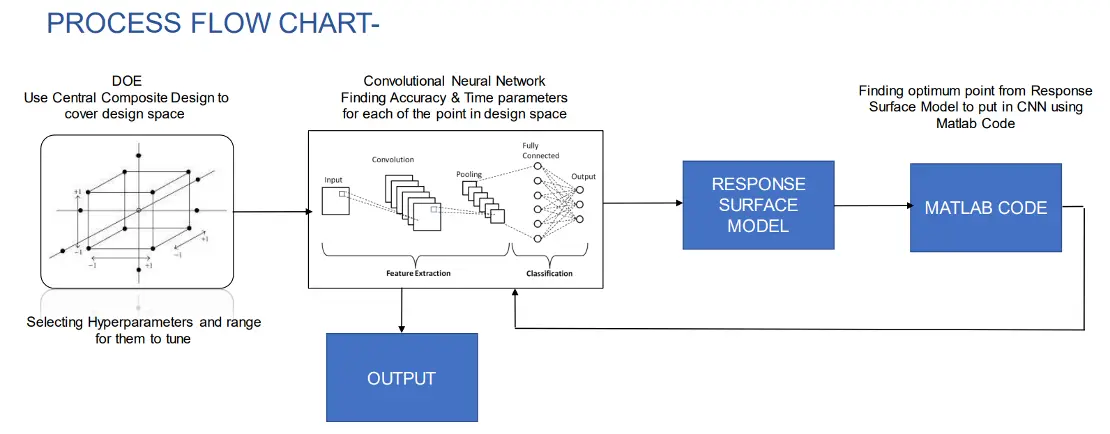

PROCESS FLOW CHART

WHAT?

The aim is to find the best

combination of hyperparameters

for a CNN model focusing on

minimizing the error and training

time

HOW?

Method involves using Central

Composite Design for Design of

Experiments. CNN's performance is

evaluated based on accuracy and

time, and Response Surface Model

identifies optimum point

RESULTS

The project successfully fine-

tuned a CNN's hyperparameters,

achieving a balance between

lower error rates and reduced

training time